![[Translate to EN:] Fahr-Lenk-Antrieb für FTS [Translate to EN:] Fahr-Lenk-Antrieb für fahrerlose Transportsysteme](/fileadmin/_processed_/2/6/csm_Fahreinheit_vo_01063_RGBkl_576b8d44c2.jpg)

Gear solutions for automated guided vehicles

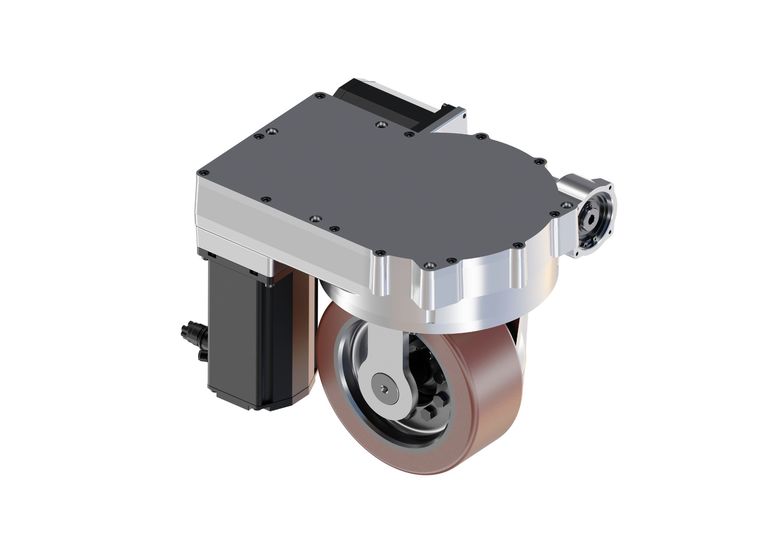

SPN traction-steering drive eco-line

GOOD TO KNOW

This patented traction drive was developed to be more compact, more powerful and even more economical. Thanks to our expertise and based on our many years of experience in the field of worm, helical and bevel gearboxes, we were able to realise this solution in a very short time.

Your advantages

- omnidirectional driving

- closed drive system

- very compact installation space

- high efficiency

- various motors can be connected (also power-dependent)

- no enveloping circle

- wheel endlessly freely rotatable

- low wheel wear due to optimised gear ratio

- no cable wear

- lightweight aluminium construction

Drive-steer drive

![[Translate to EN:] Fahr-Lenk-Antrieb für FTS [Translate to EN:] Fahr-Lenk-Antrieb für fahrerlose Transportsysteme](/fileadmin/_processed_/2/6/csm_Fahreinheit_vo_01063_RGBkl_576b8d44c2.jpg)

GOOD TO KNOW: The steering/travel drive combines two drives in one complete system. The motor for the driving axle can be controlled independently of the steering axle.

When a steering movement occurs, the travel movement is mechanically compensated by the steering movement.

This drive is particularly suitable for an area-moving travel profile. Your advantages

- Compact travel/steering unit

- Travel drive with an optimally combined gear train

- Steering drive with a self-locking gear combination for energy-saving regulation

- 360° endlessly swiveling drive wheel for precisely positioned maneuvering movements

- during the steering movement the travel movement is compensated mechanically

- brake arrangement for the travel drive optimized in terms of size and installation space

- travel speeds up to 10 km/h

- drive loads up to 1.25 t

- Maintenance-free for up to 20,000 hours

![[Translate to EN:] Flächenbewegliches Fahren für FTS mit Fahr-Lenk-Antrieb [Translate to EN:] Flächenbewegliches Fahren für FTS mit Fahr-Lenk-Antrieb](/fileadmin/_processed_/9/3/csm_iStock-1216146401_b_228bb5bc7b.jpg)

Coaxial wheel hub drive

![[Translate to EN:] Koaxialer Radnabenantrieb für FTS [Translate to EN:] Koaxialer Radnabenantrieb für FTS](/fileadmin/_processed_/0/5/csm_RC25_1_2_Rad_perspektive-Visualisierung_Kopie_d0392c9e59.jpg)

GOOD TO KNOW: A planetary gear is used for the coaxial wheel hub drive.

The motor is located directly behind the wheel without axle offset. This results in a cylindrical structure from the wheel to the motor.

This drive can be used as a direct drive or as a differential drive and can be combined with a steering drive to form a drive-steer unit. Your advantages

- compact design with very short overall length

- direct motor mounting

- wheel can be mounted directly

- integrated wheel bearing for high loads

- very high efficiency

- maintenance-free

![[Translate to EN:] FTS mit koaxialem Radnabenantrieb in der Intralogistik [Translate to EN:] FTS mit koaxialem Radnabenantrieb in der Intralogistik](/fileadmin/_processed_/a/2/csm_iStock-1294795475_b_065c1a801b.jpg)

Axle-shifted wheel hub drive

![[Translate to EN:] Achsversetzter Radnabenantrieb für FTS [Translate to EN:] Achsversetzter Radnabenantrieb für FTS](/fileadmin/_processed_/4/9/csm_MLR_Fahrantrieb_1_7d9e844158.png)

![[Translate to EN:] Achsversetzter Radnabenantrieb für FTS [Translate to EN:] Achsversetzter Radnabenantrieb für FTS](/fileadmin/_processed_/3/8/csm_MLR_Fahrantrieb_2_f50c5e15eb.png)

GOOD TO KNOW: The axle offset between the wheel and the motor is realized with a spur gear.

The design has particular advantages for very narrow track gauges, where motors with a coaxial drive would be too close together.

The axle offset makes the wheel axle freely accessible on the rear shaft end.

This makes it possible to mount an encoder or a brake, directly on the wheel axle, without a gear stage.

Your advantages

- compact design

- low torsional backlash

- precise controllability of the motors (at high speeds and with narrow track widths)

- high efficiency

- noise optimized

- loads up to 1 ton

- offset between input & output for opposite motor arrangement

![[Translate to EN:] FTS mit achsversetztem Radnabenantrieb in der Intralogistik [Translate to EN:] FTS mit achseversetztem Radnabenantrieb in der Intralogistik](/fileadmin/_processed_/8/6/csm_iStock-1207577062_b_49801559d8.jpg)

Shuttle drives for warehouse logistics

Traction drive for shuttle

![[Translate to EN:] Shuttle-Fahrantrieb für FTS [Translate to EN:] Shuttle-Fahrantrieb für FTS](/fileadmin/_processed_/c/a/csm_Beween_Liftantrieb_Lagertechnik_2_386a819a26.png)

GOOD TO KNOW: A pair of wheels offset by 90° is driven by a motor.

One wheel moves the shuttle in the longitudinal direction, a second wheel in the transverse direction. Your advantages

- 2x wheel offsets by 90 degrees for direction changes

- arrangement of the motor by 90 degrees

- direct mounting possibility

- universal motor attachment / tangential clamping

- can be used for two different shuttle sizes

Lift drive for shuttle

![[Translate to EN:] Shuttle-Liftantrieb für FTS [Translate to EN:] Shuttle-Liftantrieb für FTS](/fileadmin/_processed_/f/4/csm_Beewen_Schneckengetriebe_2_837e7327e2.png)

GOOD TO KNOW: To bring the wheels on the rails into engagement, the lift gear lowers or raises the position of the shuttle on the respective rail. Your advantages

- universal motor attachment / tangential clamping

- optimized oil lubrication for position operation

- accessible relubrication possibility

- customized stiffened connection

- manual drive possible

![[Translate to EN:] Shuttle-Antrieb für FTS in der Intralogistik [Translate to EN:] Shuttle-Antrieb für FTS in der Intralogistik](/fileadmin/_processed_/c/1/csm_iStock-1302200916_b_b05b2531b1.jpg)

Steering drive

![[Translate to EN:] Lenkantrieb für FTS [Translate to EN:] Lenkantrieb für fahrerlose Transportsysteme](/fileadmin/_processed_/1/4/csm_Vxx_Lenkantrieb_Design_Step_full-Visualisierung_Kopie_eb2a87ee24.jpg)

GOOD TO KNOW: The steering-only drive can be further developed in combination with a travel drive to form a travel-steering unit.

However, it can also be used as a pure steering drive in a three-wheel concept.

Thanks to its encapsulated design, the steering drive is insensitive to dirt and does not require relubrication. Your advantages

- compact design, optionally with cone pre-stage

- separate traction drive due to hollow shaft of the steering drive

- closed design

- maintenance-free design

Further information on automated guided vehicles

Gearbox solutions for AGVs

Gearbox solutions for automated guided vehicles (AGVs)

Download detailed information on SPN transmission solutions for automated guided vehicles.

Industry examples for further SPN drive solutions

Your contact for your industry solution