Planetary gear units to the SPN standard

SPN planetary gear units excel due to their wide range of possible applications. High rigidity combined with low radial backlash for their dynamic positioning role. A highly efficient, compact design for continuous operation of your smart solution. Or optimal smooth running properties through ground helical gears. What do you consider to be important when selecting a gear unit? You decide which requirements your gear unit should fulfil.

SPN planetary gearboxes are easy to customize, even for special applications. Complete special transmissions for many industries and exceptional requirements can also be developed and produced. Our process for the special transmission is transparent and cost-conscious. See for yourself.

The common practice in SPN is to adapt standard gears, as in this case. In an example in food processing, compliance with hygiene standards was anchored in the requirements for the planetary gearbox.

Discover your customization options

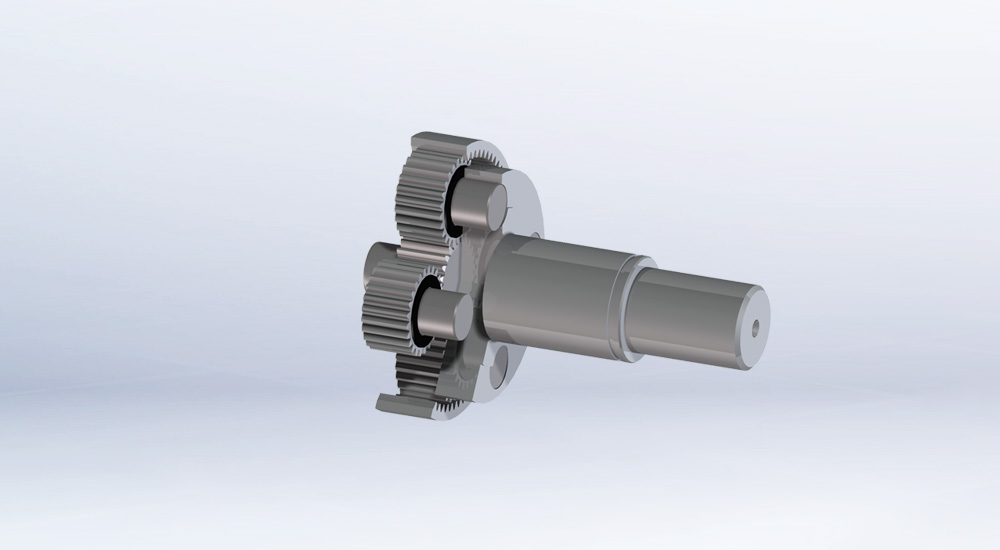

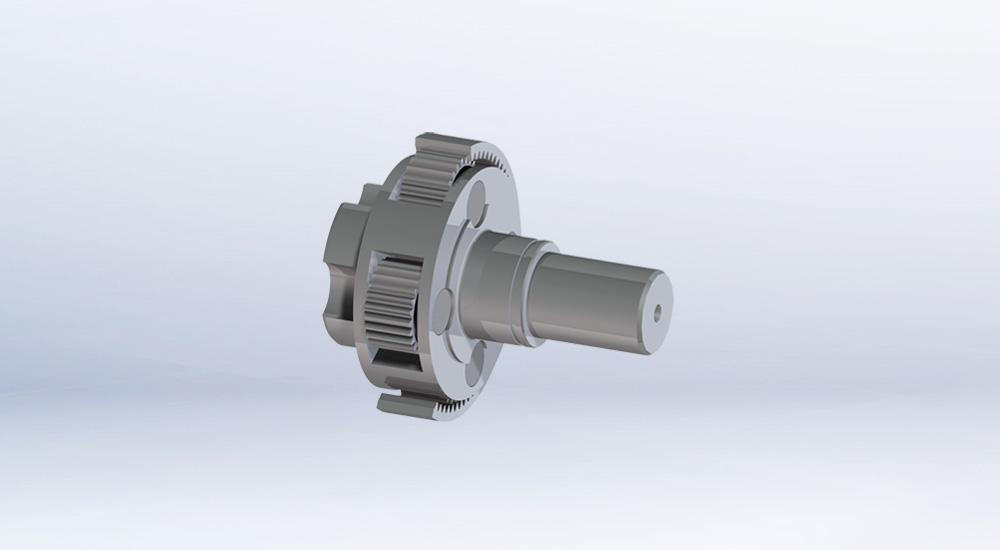

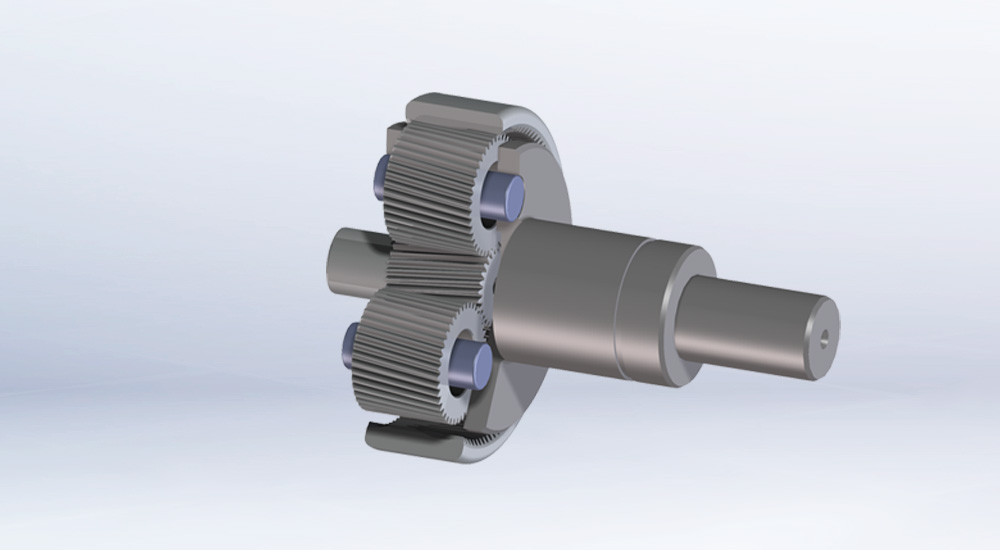

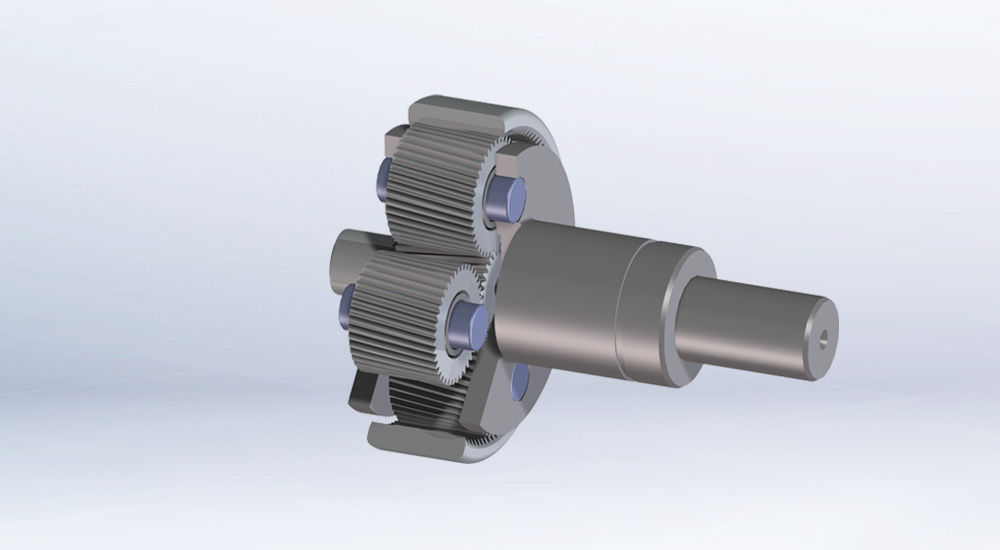

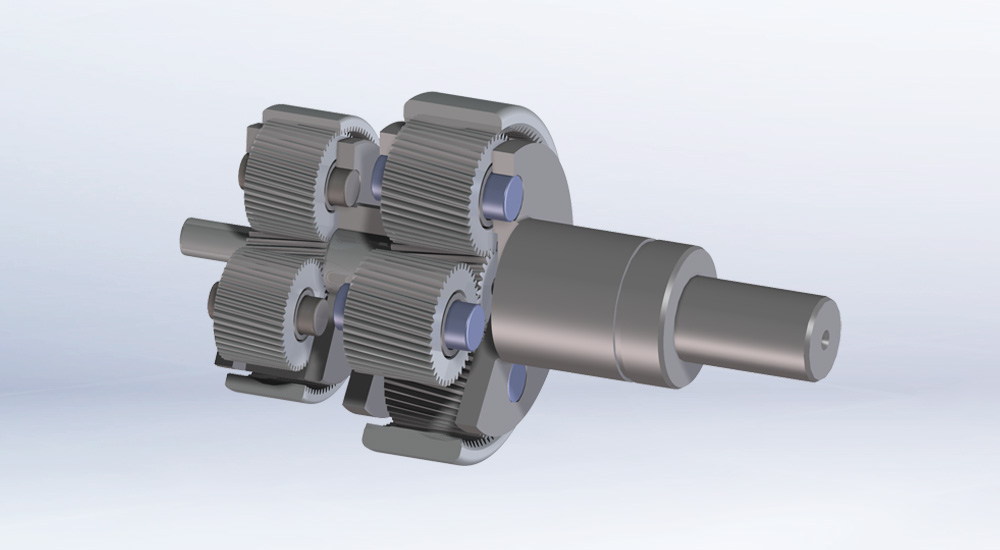

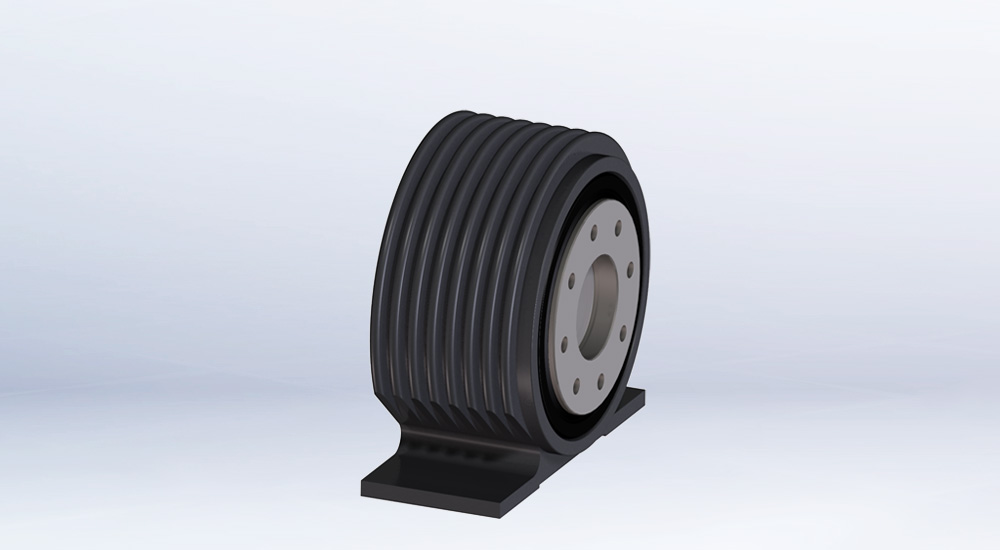

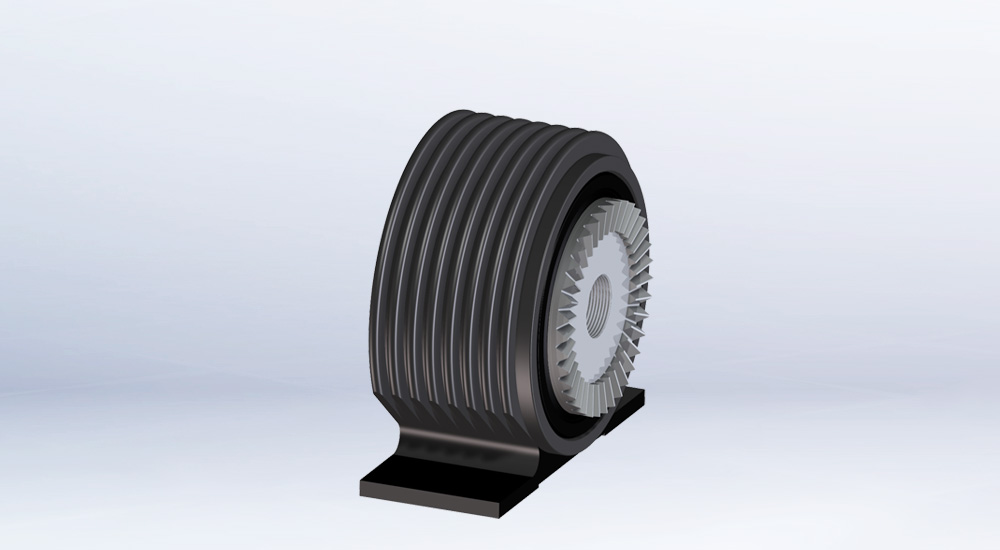

Basic design of planetary gear units

The basic design of a planetary gear unit consists of a sun gear, a ring gear and several planetary gears. The planetary gears are supported by the ring gear and rotate around the sun gear. This operating principle gave the name to this type of gear unit. The gear unit's drive and output functions can be performed by the sun gear, the housing or the planetary carrier, depending on the design.

In the most common design, the epicyclic gear unit, the drive function is performed by the sun gear, the output function by the planetary carrier, and the housing is stationary. This design has a positive influence on the internal forces in the gear unit. The load distribution over several planetary gears enables high torques to be transmitted in a compact design. The use of helical gears reduces the running noises.

These are the advantages of planetary gear units to the SPN standard

- Compact

- High torque can be transmitted

- Drive and output run synchronously

- Coaxial design

- Minimal radial backlash

- High efficiency

- High degree of stiffness

These SPN products are more suitable for the following characteristics

- Self-locking SPN worm gear units

- Offset axes SPN helical gear units

- Angled output SPN bevel-helical gear units

- Hollow shaft SPN bevel-helical gear units

The SPN series at a glance

E- P88-S-VA planetary gear unit - keeping you clean

GOOD TO KNOW

The gear unit was developed for applications from the hygienic sector. Due to the seamless design and the choice of materials, the gear unit can be used process-integrated in the Hygienic Design Zone.

YOUR BENEFITS

- high corrosion protection - external components are made of stainless steel 1.4404

- operating temperature below 60°C in S1 operation due to finely tuned part systems

- high flexibility due to different gear ratios

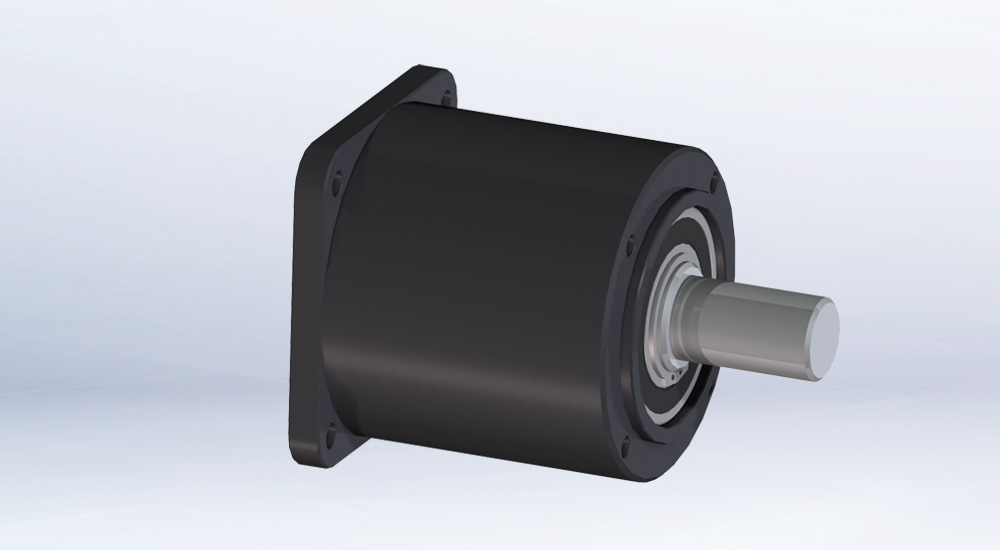

Planetary gearhead X- P118-F-DM - for more power

GOOD TO KNOW

This gearmotor unit has been specially developed for maximum power density. The direct connection between motor and gear unit saves overall length and mass inertia. This allows the unit to be operated particularly dynamically.

YOUR BENEFITS

- compact design due to direct motor attachment

- low inertia - coupling parts between motor and gear unit are not required

- High rigidity due to optimally dimensioned flanged shaft

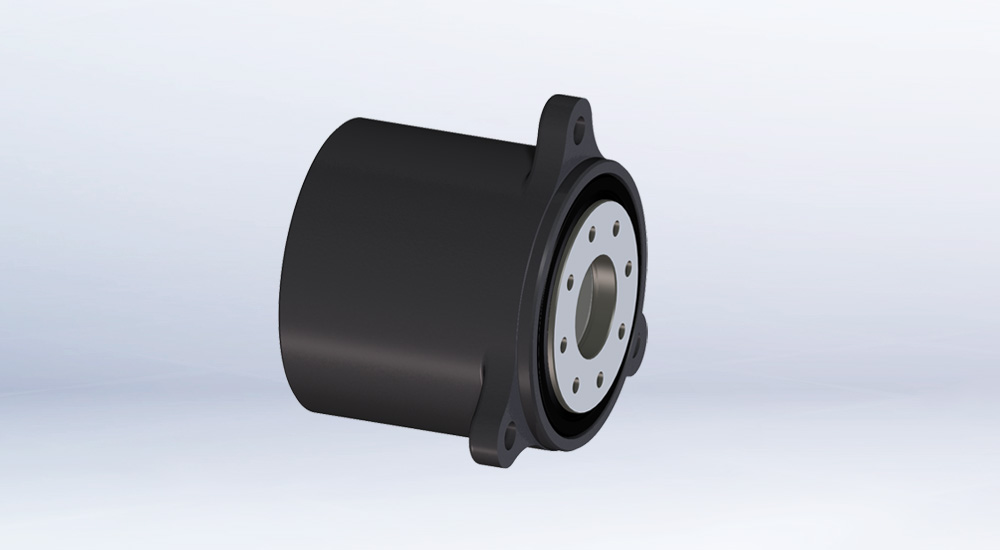

PU4 planetary gear unit - light-footed powerhouse

GOOD TO KNOW

The planetary gear units of the PU4 series stand for power density. The use of modern materials in combination with innovative ideas makes for a gear unit of contrasts. A powerhouse that impresses with its lightness. Powerful in performance data but still with the best values for mass inertia. Technically at the highest level.

YOUR BENEFITS

- high acceleration - thanks to an inertia-optimized motor connection

- high torque - due to wide, double-bearing planetary gears

- high rigidity - due to large shaft dimensions

- high permissible radial forces - due to tapered roller bearings with optimized bearing spacing

- Low torsional backlash - due to paired drive components

- low running noise - due to ground helical gearing

- easy motor mounting - due to tangential clamping with sun gear fixation

- variable - due to any mounting position

- maintenance-free - due to lifetime lubrication with synthetic gear oil

- low energy consumption - due to high efficiency

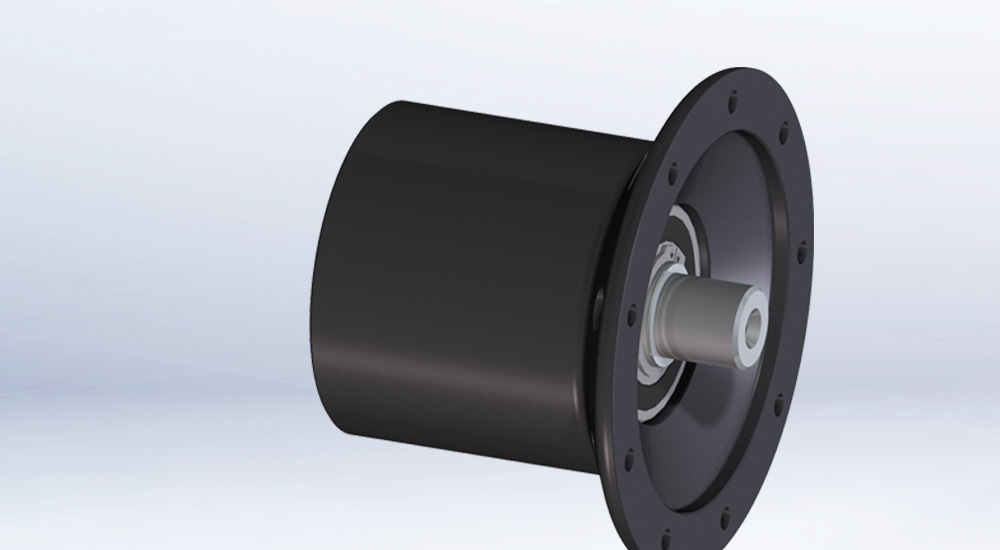

RC4 planetary gear unit - the plus in rigidity

GOOD TO KNOW

The planetary gear units of the RC4 series are designed with a flanged shaft. The solid flanged shaft exhibits high torsional stiffness and is thus particularly suitable for positioning tasks. Fittingly, the radial backlash is less than one minute of arc. RC4, the gear unit that cuts to the chase.

YOUR BENEFITS

- High degree of stiffness – due to optimised shaft size

- Low radial backlash – due to paired drive components

- High acceleration – due to a motor connection with optimised inertia

- High torque – due to wide planetary gears mounted in two bearings

- High permissible radial forces – due to roller bearings with optimised bearing spacing

- Low running noises – due to ground helical gears

- Simpler motor mounting – due to tangential clamping with sun gear fixation

- Variable – through freely selectable mounting positions

- Maintenance-free – through lifelong lubrication with synthetic gearbox oil

- Low energy consumption – due to high efficiency

E2 planetary gear unit - economical all-rounder

GOOD TO KNOW

The planetary gear units of the E2 series are ideal for your subordinate applications. With up to three different drive versions, you will always find the right solution. The simple but rugged design allows it to be manufactured economically.

YOUR BENEFITS

- Flexible – due to different drive sizes

- Variable – through freely selectable mounting positions

- Simpler motor mounting – through tangential clamping with sun gear fixation

- Maintenance-free – due to lifelong lubrication with synthetic gear grease

- Low energy consumption – due to high efficiency

PUK4 - the powerhouse with an angled stage

GOOD TO KNOW

Like the basis gear units of the PU4 series, power density also takes centre stage here. The addition of an angled stage allows these gear units to be used in confined spaces. A wide range of gear ratios can be achieved due to the combination of low-loss cyclo-palloid gears and low-noise helical gears. Thanks to their low moment of inertia, these gear units are ideal for highly dynamic applications.

YOUR BENEFITS

- Space-saving – due to the angled preliminary stage

- High acceleration – due to a motor connection with optimised inertia

- High torque – due to wide planetary gears mounted in two bearings

- High degree of stiffness – due to large shafts

- High permissible radial forces – due to tapered roller bearings with optimised bearing spacing

- Low radial backlash – due to paired drive components

- Low running noises – due to ground helical gears

- Simpler motor mounting – through tangential clamping with sun gear fixation

- Variable – through freely selectable mounting positions

- Maintenance-free – through lifelong lubrication with synthetic gearbox oil

- Low energy consumption – due to high efficiency

EK2 - the powerhouse with an angled stage

GOOD TO KNOW

The basic gear units of the E2 series already stand for flexibility. The addition of an angled stage places even greater emphasis on this feature. With this variant, you enjoy even more freedom in your available installation space.

YOUR BENEFITS

- Space-saving – due to the angled preliminary stage

- Flexible – due to different drive sizes

- Variable – through freely selectable mounting positions

- Simpler motor mounting – through tangential clamping with sun gear fixation

- Maintenance-free – due to lifelong lubrication with synthetic gear grease

- low energy consumption - due to high efficiency

E2 stainless steel – guaranteed corrosion-proof

GOOD TO KNOW

The gear unit for your hygienic applications. The gear units of the E2 series are also available in stainless steel for use in the pharmaceutical and food industries.

YOUR BENEFITS

- Safe – due to use of shaft seals

- Corrosion-proof – due to use of high-quality stainless steels

- Flexible – due to different drive sizes

- Variable – through freely selectable mounting positions

- Simpler motor mounting – through tangential clamping with sun gear fixation

- Maintenance-free – due to lifelong lubrication with synthetic food-grade gear grease

- Low energy consumption – due to high efficiency

- Space-saving – also available with angled preliminary stage