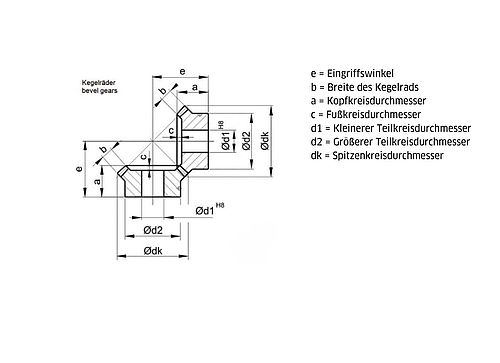

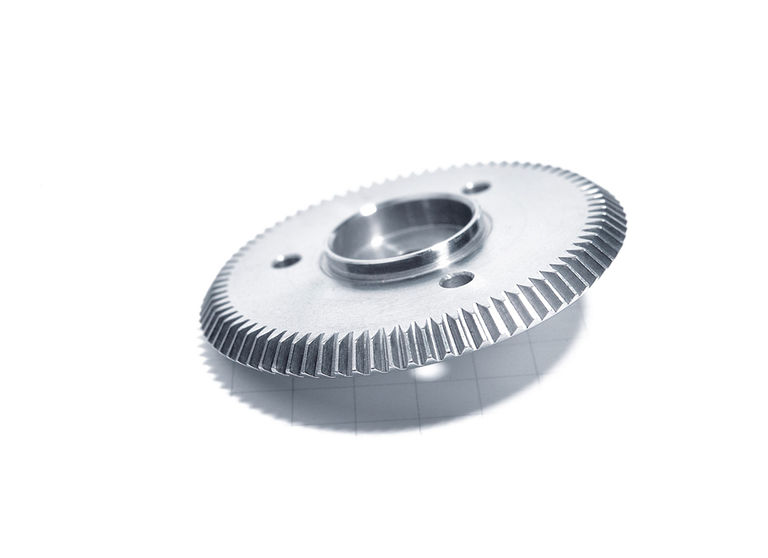

A bevel gear is a gear consisting of two conical gears whose teeth are arranged on the wheel surface. The tooth height is the vertical size of a tooth profile from the base circle line to the tooth tip. The tooth root height is the distance from the base circle line to the tooth root line.

The respective amounts increase the more you move outwards on the taper line.

- The tooth width (b) indicates the radial width of a tooth, measured along the cone generatrix.

- While the pitch (p) describes the distance between two consecutive teeth on the same taper circle line.

- The module (m) represents the ratio between the pitch and π.

- The transmission ratio (i) is the ratio between the speed of the driving wheel and that of the driven wheel.

In addition, the angle between the axes of the bevel gears is referred to as the bevel angle. This angle influences the way in which the forces are transmitted between the wheels. There are any number of bevel angles, but the majority of bevel gears are in the 90° range.

Source: Bevel gear set brass 1:1 module 0.5 - 20Z | bevel gears | gearing parts | eSYS.co