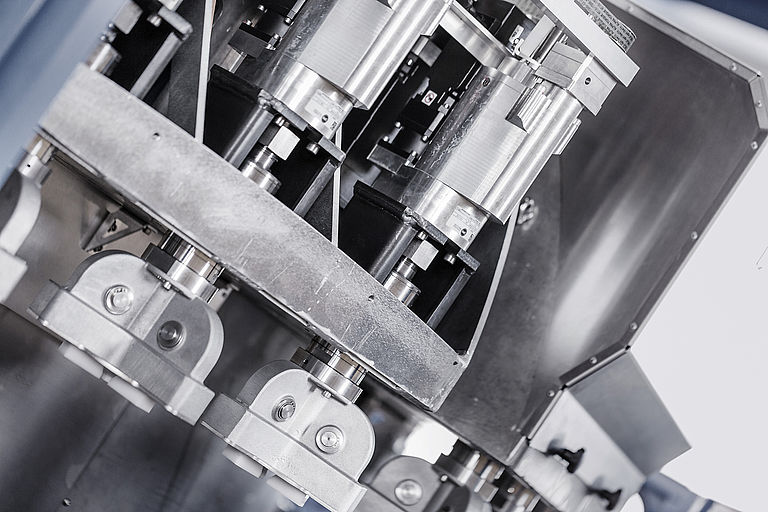

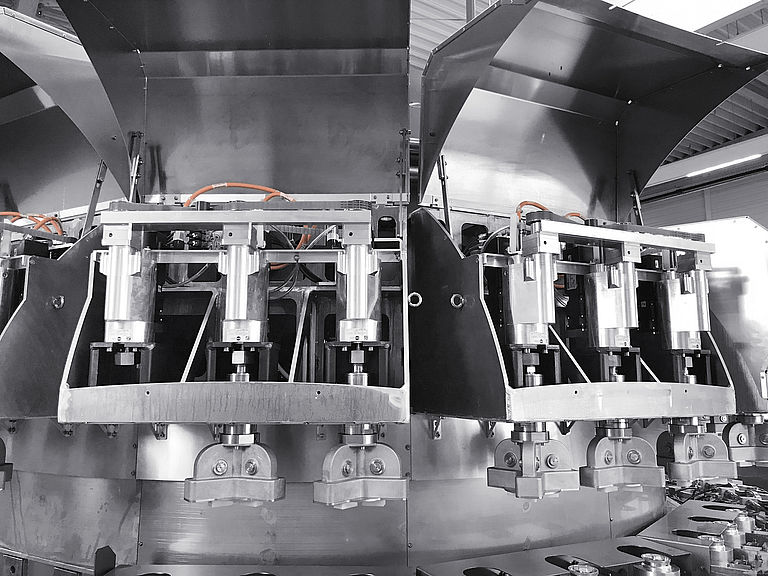

In a new high-speed plant for the glasses production, a lift-turn-unit positions the glass blanks extremely fast. This custom-made drive of SPN is characterized by a positioning accuracy between the individual work steps, which is important to assure that the filigree glasses are not damaged.

Thus, SPN could develop a total concept which realizes the glasses production with a single plant instead of two in the past. The used lift-turn-unit is a gearbox with hollow shaft and output flange. The necessary connection cables can be laid through the hollow shaft to the gripper on the output side. Furthermore, the output flange of the flange drive is suitable for fixing the gripper. In this process, the grippers capture the glasses and bring them – after they have been lasered and ground – into position for the corresponding tray. At the same time, a rotational movement takes place within which the glass is captured and turned with a speed of 370 U/min. With this plant, up to 60 glasses per minute, i.e. up to 60,000 per day, can be produced.