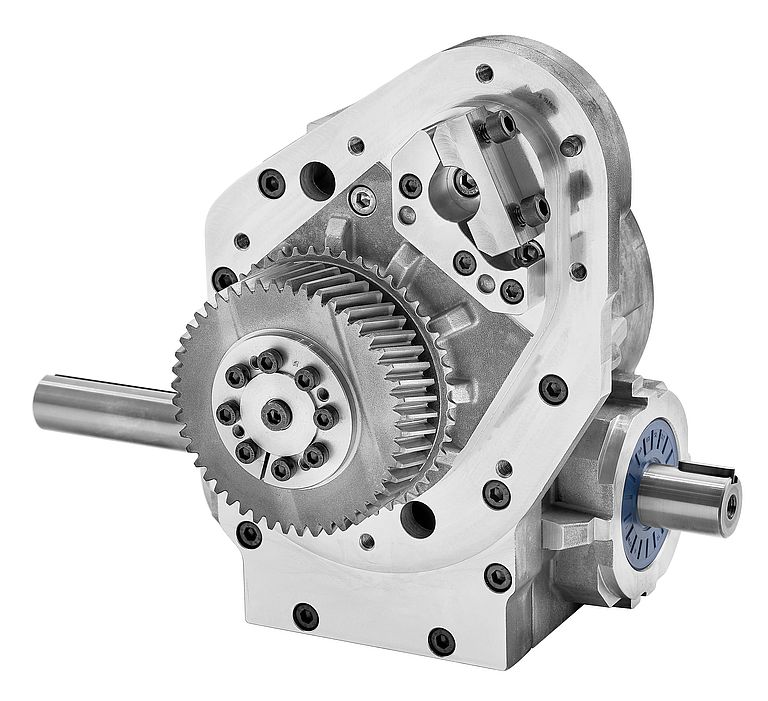

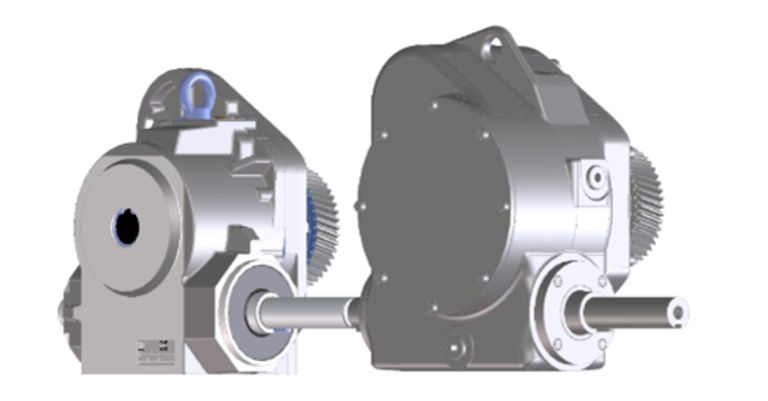

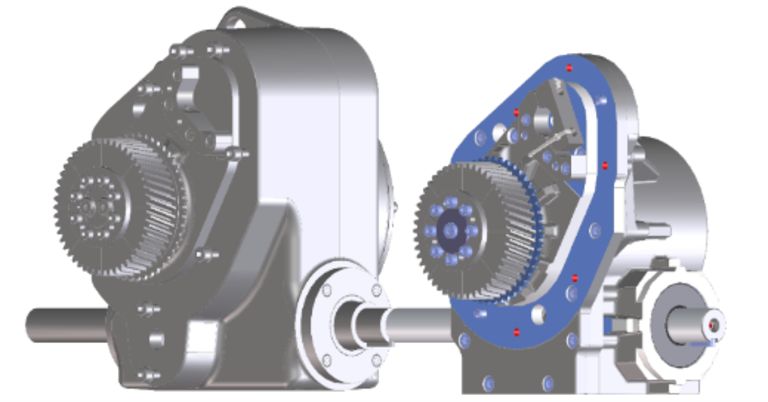

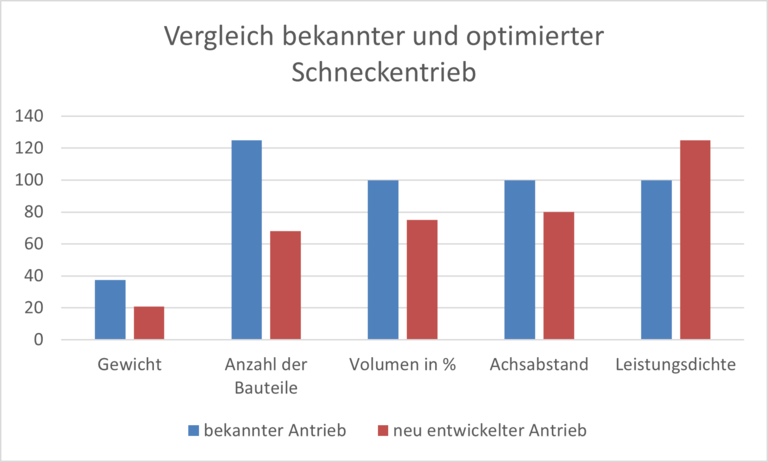

SPN has developed, produced and assembled a worm gear unit especially for the drive of a weaving machine. The gear is driven by a toothed belt or by a toothed belt wheel on the worm shaft. The drive set consists of a case-hardened worm shaft and a bronze worm wheel and has a center distance of 80 mm, with a transmission ratio of i=8:1. In order to achieve the target price, among other things the center distance was reduced and a higher power density was achieved. Various auxiliary units are driven by the worm shaft via additional belt wheels. In addition to the helical spur gear, the output shaft also has a sprocket wheel which drives the oil pump of the machine-side continuous lubrication of the gearbox. The axle of the counter gear is clamped by a steel component integrated into the gear housing. The gearbox housing consists of 2 aluminium chill castings.

The decision to design the gearbox with the reduced center distance was made at the end of 2018. After some detailed discussions the proposed design could be released in March 2019. This new development was completed at the end of May 2019. Already in mid-September 2019 the first gearboxes could be assembled and delivered. The machines of our end customer are now in operation worldwide with our gear unit.