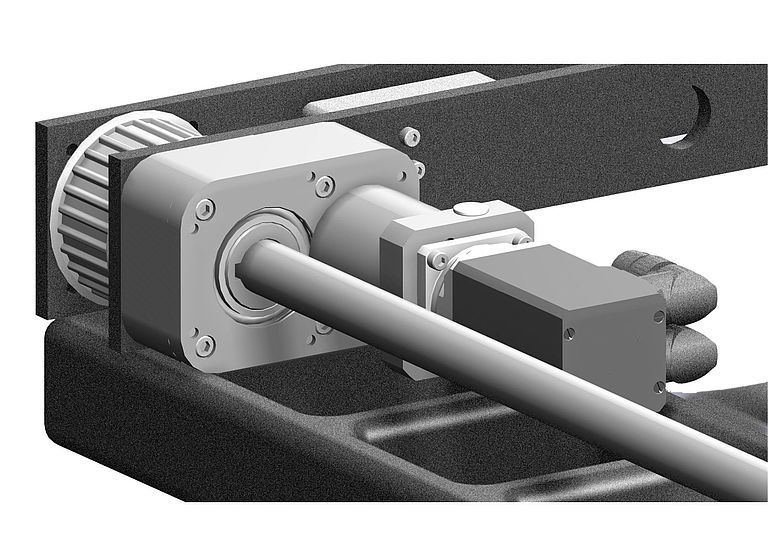

The customer company, a plant manufacturer from southern Germany, required a gear unit to drive conveyor belts on which - as part of the changing system of a plant for additive manufacturing - heavy components could be transported. The special requirement that this gearbox had to meet was primarily the limited installation space available for it. This was not only limited at both ends of the shaft by the distance between the two belt pulleys of the conveyor belt; the height was also specified by the diameters of the belt pulleys. At the top, the gear unit was not allowed to reach the conveyor belt itself; at the bottom, the machine bed limited the dimensions for the components (see Figure 1).

Suitable for all dimensions: Application example for a drive solution with limited installation space

Designing high-performance gear units for limited installation spaces is one of the unique selling points of SPN Schwaben Präzision. The development of such a gearbox for a changing system once again proved how well the principle of "adapting standard parts" works in practice.

Initial situation

Figure 1: Constricted installation space in height, between machine bed (bottom) and conveyor belt (top)

The first question was which type of gearbox would be functionally best suited for this particular requirement.

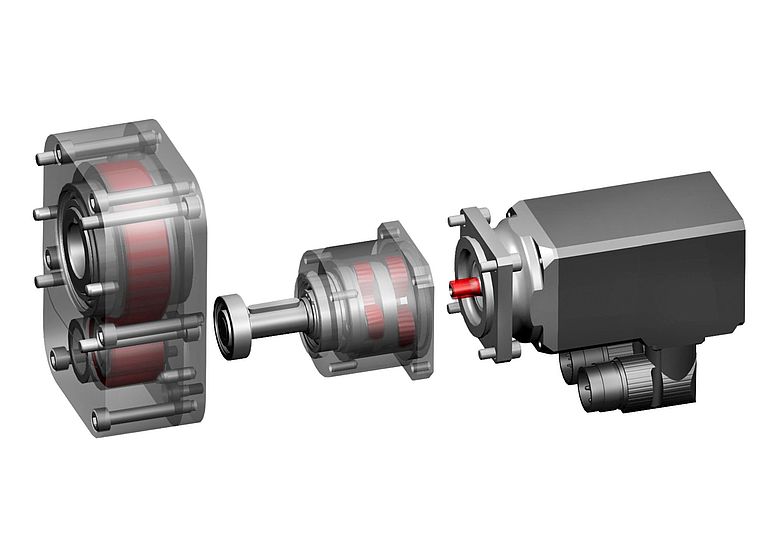

The decision was finally made in favor of a helical gear unit with a hollow shaft in combination with a planetary stage. It is true that the use of other types of gear unit would also have been possible: However, the advantage of this design was that SPN was able to assemble the necessary components on a large scale from its own standard catalog and guarantee not only a correspondingly shorter development and construction time, but also a comparatively low price.

Requirements and development process

Once the basic requirements had been clarified with the customer, the next step was to work out a concrete design for the construction of the gearbox. Simon Reiber, the SPN product manager responsible for managing this project and for the further development of the products: "The task we had to solve here was to adapt the components without restricting the functionality - this applied in particular to the restrictions imposed on us by the tightly dimensioned installation space. What was particularly challenging here was the height, i.e. the distance between the machine bed and the conveyor belt, for which we then had to resort to appropriate components." Beyond the specific project, the SPN designers also thought about solutions for how a gear design could be realized with an even smaller longitudinal dimension between the two belt pulleys. Reiber: "We wanted to use this practical example to develop further solution variants for limited installation spaces, especially with a view to the future. In this context, a possible shortening of the longitudinal axis seemed to us to be quite practically relevant as a future option." The advantage: "Should we be confronted with comparable requirements in the near future, we already have the corresponding designs for them in the drawer and can start implementing them immediately." In the practical application at the customer's site, but also in the parallel design carried out for internal purposes, the combination of standard components with the corresponding customer-specific adaptations was the central component of the final elaborated solution. "We have now established ourselves as specialists for this type of solution in our areas of application," says Reiber: "With our comprehensively stocked catalog of gearbox components on the one hand and the development expertise of our technicians on the other, we are able to implement gearbox solutions in quantities ranging from 50 to 1000 with an excellent quality/price ratio. This is of particular benefit to those machine and plant builders who attach importance to a fully-fledged system solution tailored to their specific requirements, but at the same time want to keep costs as low as possible."

Project implementation

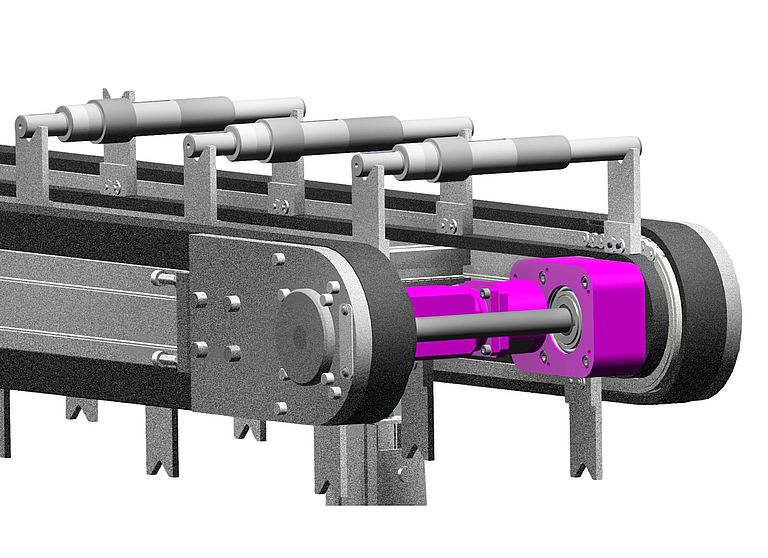

For the implementation of the internal model project, a solution was finally developed that allows the use of a full-fledged drive for the conveyor belt even with clearly shorter wheel distances. Figures 2 and 3 show what the actual implementation looked like, or could look like. Figure 2 is a simplified representation of the customer's specific application. The limitations of the installation space in all directions, which are a prerequisite for the unrestricted function of the conveyor belt, are clearly visible here.

Figure 2: Application case in the model project, reduction of the axial overall length, between the two belts (left and right).

Figure 3 shows, optionally, the "model solution" as it was developed with emphasis on the longitudinal dimension of the gear unit (or distance between the two conveyor belt wheels). The solution here essentially consisted of placing the gear unit - without a clamping unit, without a sealing ring and, without further bearings - in direct meshing with the motor.

Figure 3: Solution approach of the short build version

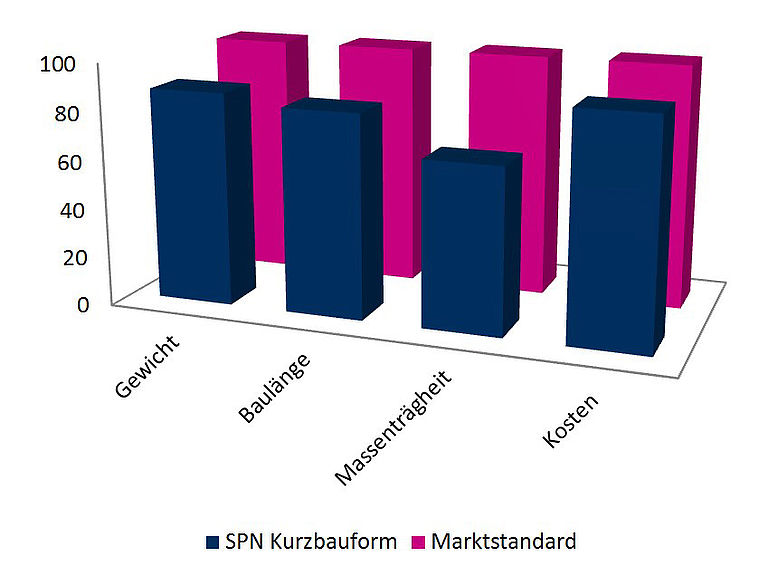

Furthermore, it was possible to optimize the placement of the two bearings on the output of the planetary gearhead with regard to the installation space, thus saving further length. This solution is more compact, space-saving and weight-saving than any standard solution (which must always cover a certain range of possible applications), see the table (Figure 4) and Figure 5.

Figure 4: Parameters for comparison of both solutions

As in the specific, ultimately less complicated application at the customer's, the essential principle of this solution is to use standard parts, but to modify them with regard to the final finish in such a way that the customer has a complete solution that is precisely tailored to the application. Another task that had to be solved in the customer's specific application was the attachment of the gear unit to the conveyor system. After discussing various variants together, the decision was finally made in favor of a simple pin solution. All that had to be done was to drill two holes at the appropriate point on the conveyor system in order to fasten the gear unit directly to the system by means of two dowel pins. Further modifications were required for the installation of the hollow shaft, the diameter of which was adapted accordingly for an optimum fit.

Figure 5: Optical comparison of both solutions

Project result

Once again, this case confirmed how well the SPN principle of adapting basic parts for a specific application sector works. In this way, it was possible to develop a solution that took the customer's requirements into account one-to-one, while at the same time keeping a tight cost corridor in mind. Another strength of this principle - as in the entire project handling with SPN - also came into play here: the speed factor. It took less than seven days from the first telephone consultation to the first CAD model, and less than six weeks from sample order to sample delivery. In the course of a very close cooperation with the customer, the coordination was also very result-oriented on both sides. The customer expressly liked the fact that SPN responded quickly and always with concrete proposals to all challenges and questions that arose during the course of the project, so that a solution could be agreed upon quickly. "The message that we want to convey to the market in this way is always the same," summarizes Simon Reiber. It's: "Give us a project, and we'll build you a complete unit with adapted standard parts that perfectly fits your application."

Gearbox combination with motor

Download application report

Industry examples for SPN drive solutions

Your contact for your industry solution