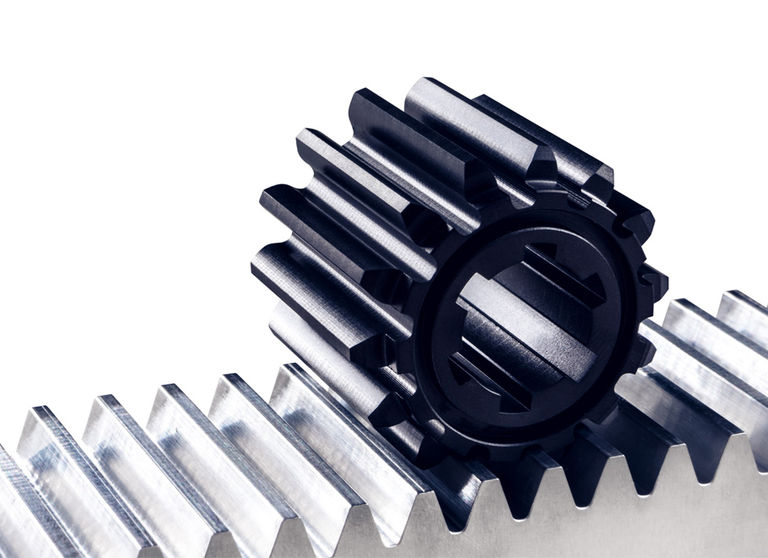

Rack and pinion gearing is a mechanical system consisting of a straight, elongated rack with a large number of teeth. The base body can be round, square, rectangular or otherwise shaped.

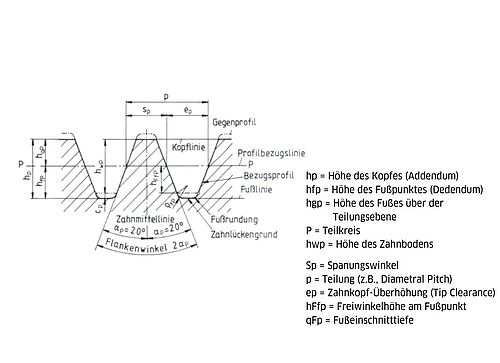

The technical designation for such a toothing comprises several parameters to precisely describe its properties. These include

the module (m), which indicates how large the teeth are in relation to the diameter of the pinion.

The tooth head width (rack width), which describes the width of the teeth at their widest point

the tooth root height, which indicates how high the teeth are from the base of the rack.

The pitch (p) is the distance between two consecutive teeth at the same point.

The pressure angle (α) is shown in the sketch above.

The tooth height refers to the total height of a tooth from the tooth root to the tooth tip.

The material from which the rack teeth are made varies and can include steel, plastic, brass or other materials. The accuracy class also plays a decisive role. This indicates how precisely the toothing is manufactured and what tolerances it meets.

Source: https://informatik.rostfrank.de/cad/lex09/lex0903.html