Bevel-helical gear units to the spn standard

The available installation space for your gear unit is getting constantly smaller – do you know that problem? With a SPN bevel-helical gear unit, you open up a new dimension. Due to the very high efficiency, you are ideally equipped for a high-power application. The availability of different designs and the ability to be combined with additional gear unit stages provides you a wide variety of options. Convince yourself of this versatility.

Discover your customization options

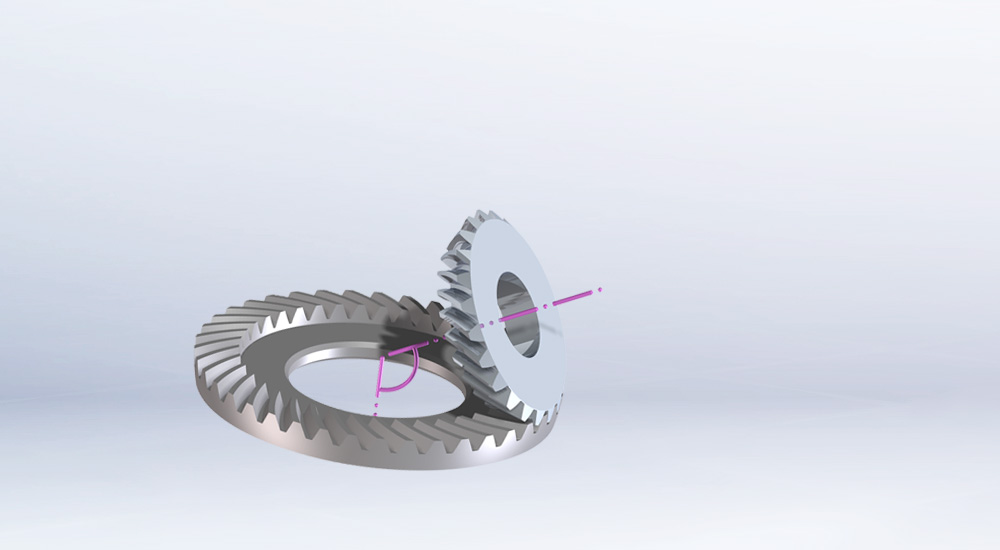

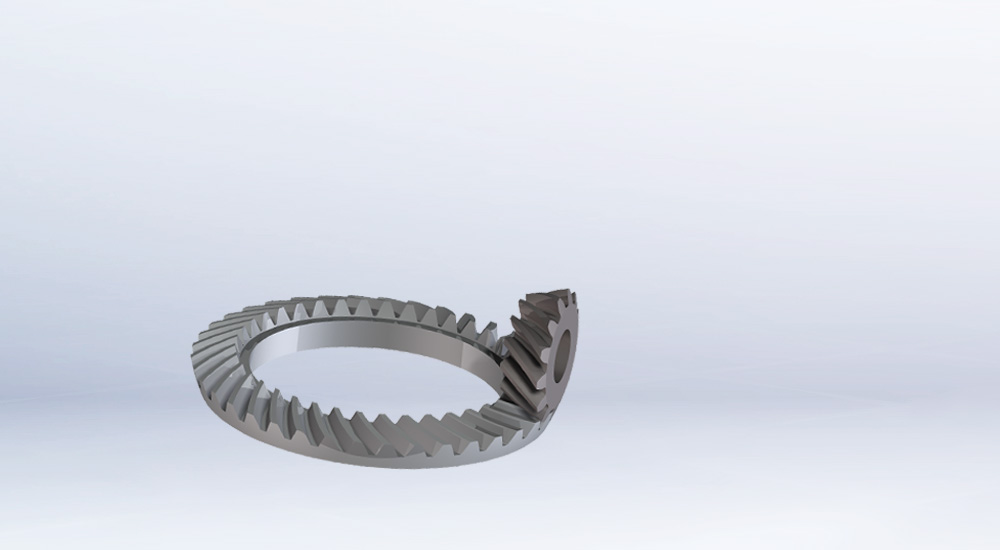

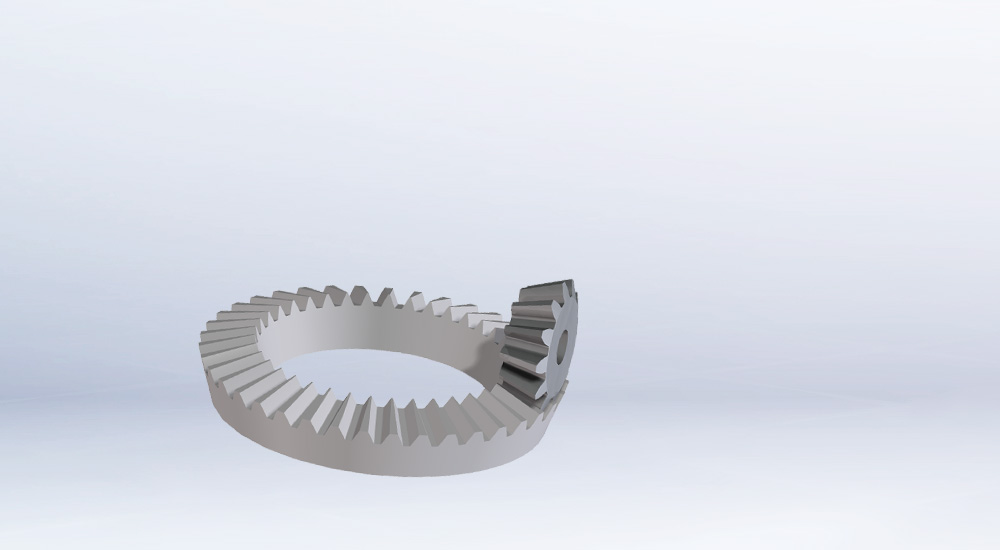

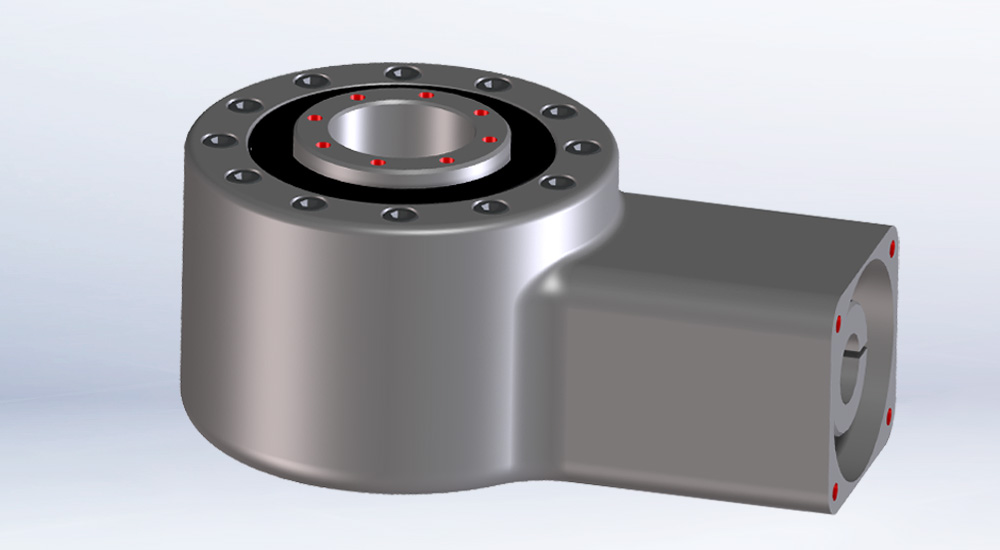

Basic design of bevel-helical gear units

A bevel-helical gear unit generally consists of a bevel crown gear, a bevel pinion and a housing. The bevel pinion drives the bevel crown gear and thus provides the gear ratio. The roller-type gearing used in the gear unit has a low proportion of sliding motion and thus ensures high level of efficiency. The drive and output shafts are arranged at an angle to each other, often at 90°, though other angles are also possible. This angular offset allows the forces to be redirected and is one of the main features of this type of gear unit. Because the driven gear is large, bevel-helical gear units are ideal when a hollow-shaft version is required. With a pure bevel-helical gear unit, the gear ratios that can be achieved tend to be smaller, for which reason they are often combined with additional gear unit stages. Planet and helical gear stages are particularly suitable for these combinations.

These are the advantages of bevel-helical gear units to the SPN standard

- Angled output

- High efficiency

- Hollow-shaft version possible

- High torque can be transmitted

- Low running noises

- Minimal radial backlash

These SPN products are more suitable for the following characteristics

- Self-locking SPN worm gear units

- Offset axes SPN helical gear units

- Compact designSPN planetary gear units

- High level of torsional stiffnessSPN planetary gear units

The spn series at a glance

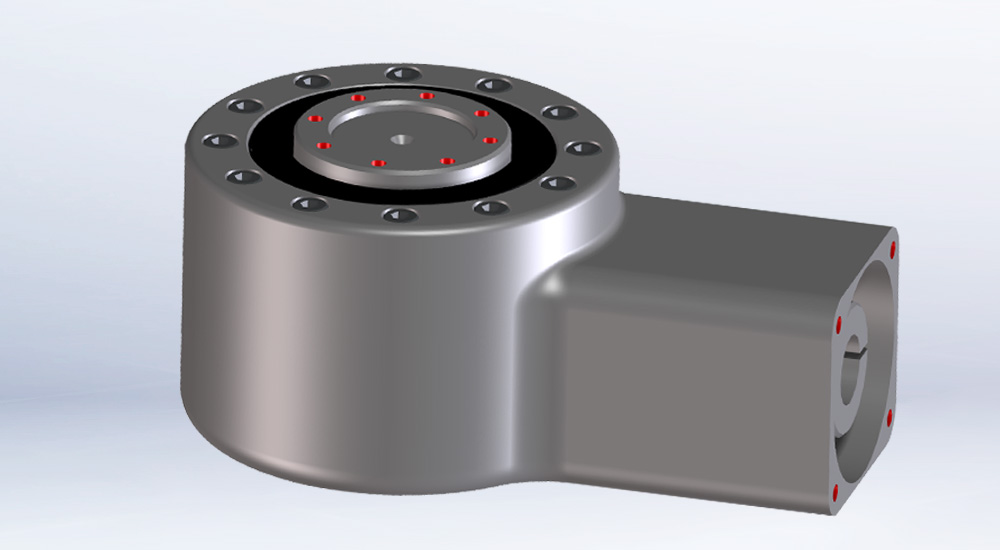

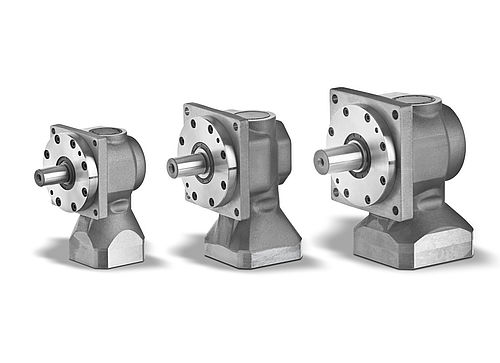

Bevel-helical gear units

GOOD TO KNOW

- Aluminum housing

- Three sizes

- Hypoid toothing

- Motor mounting with splined motor shaft

YOUR BENEFITS

- High torques – due to hypoid toothing

- High axial and radial forces – due to tapered roller bearings

- Low inertia – due to splined motor shaft